GEOSAN PE Double structured wall rigid conduit

- CLASS:SN4 | SN8

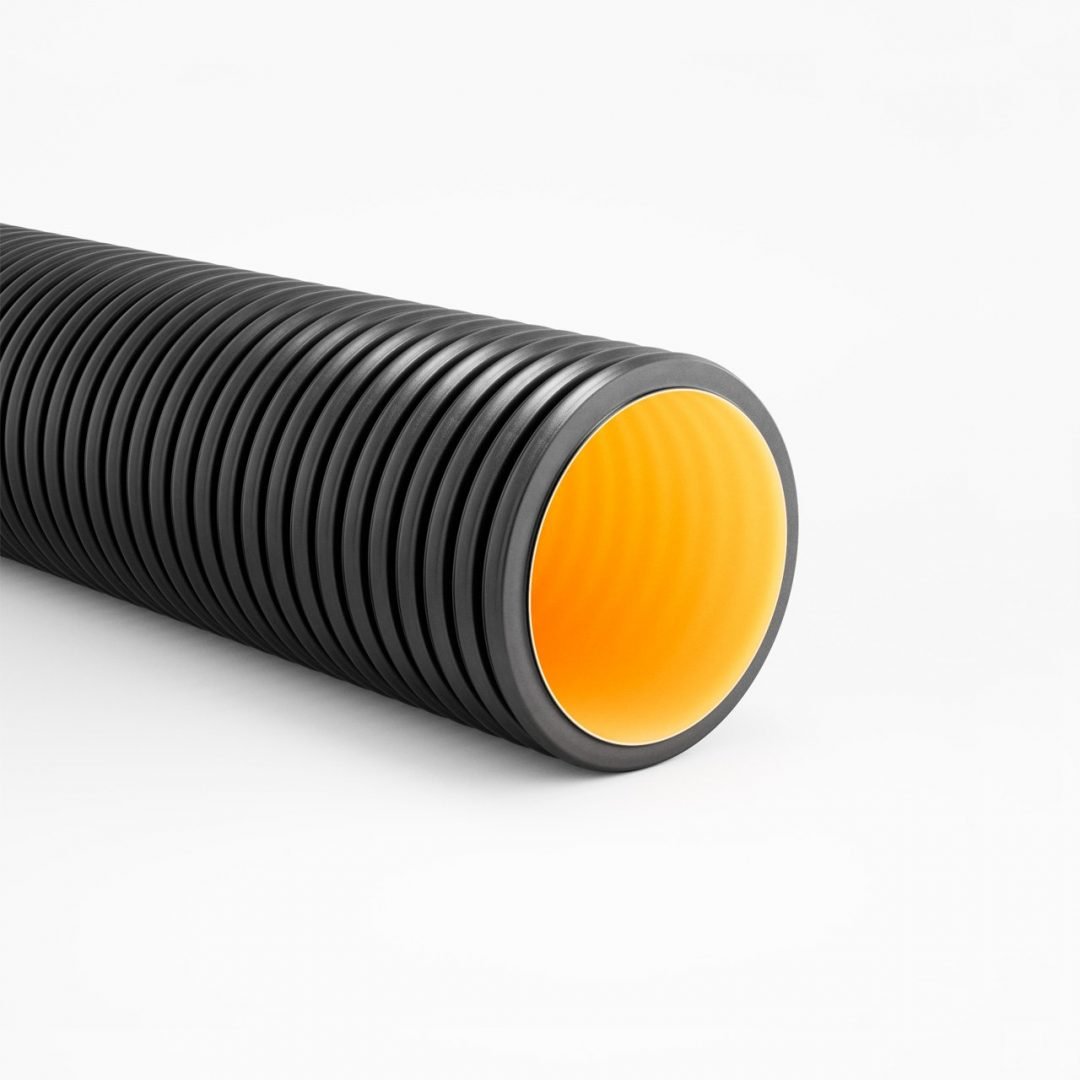

GEOSAN double structured wall pipes, corrugated outside and smooth inside, were developed by KOUVIDIS in 2012 and presented in the Greek market in 2013 as a safer and more economy solution than cement and PVC pipes. They are produced following the co- extrusion method from specially stabilized raw materials of high density polyethylene (HDPE) and are classified as SN4 and SN8 according to their ring stiffness. They are fully complied with the strict European Standard EN 13476-3 for Plastic piping systems for non-pressure underground drainage and sewerage made of unplasticized polyvinyl chloride (PVC-U), polypropylene (PP) and polyethylene (PE).

APPLICATION FIELD

They are intended for waste water collection in sewage networks as well as for the drainage of stormwater in road networks. They are also suitable for a multitude of free-flow sewage applications, such as in airports, tunnels, parking spaces, structural projects etc.

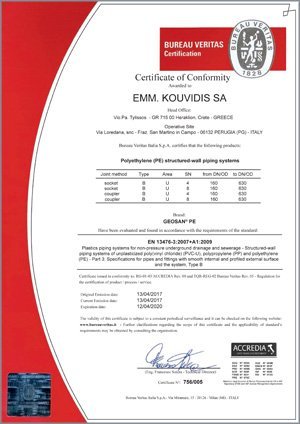

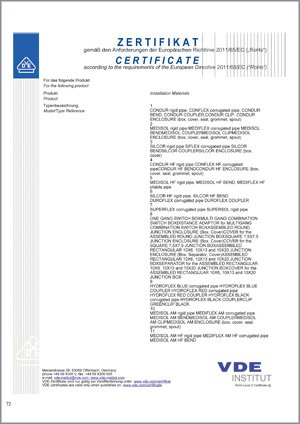

- APPLICATION STANDARD:EN 13476-3

- INSTRUCTIONS FOR COMPLIANCE:2011/65/EE (RoHS)

- COLOR:RAL 9004 black (outer layer), RAL 1017 yellow (inner layer)

- RING STIFFNESS:SN4

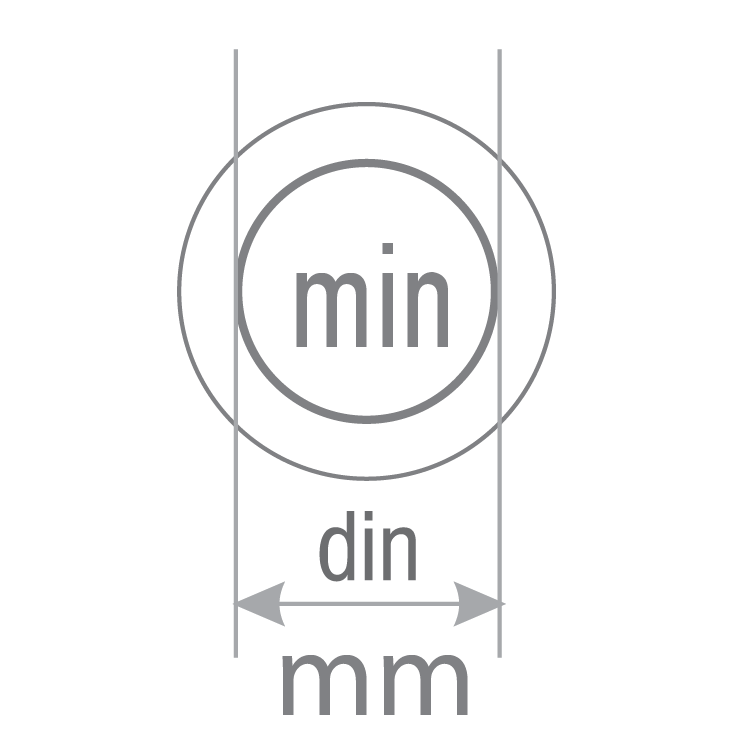

- NOMINAL DIAMETER:Nominal outer diameter (DN/OD)

Min-max permanent application temperature

Min-max permanent application temperature Product with extra UV stability

Product with extra UV stability Product is made of halogen free raw materials

Product is made of halogen free raw materials Nominal outer diameter (mm)

Nominal outer diameter (mm) Certification body of Bureau Veritas

Certification body of Bureau Veritas Raw material of production with very good behavior towards hazardous chemical substances

Raw material of production with very good behavior towards hazardous chemical substances Friction resistance

Friction resistance Ingrees protection against water EN 1277

Ingrees protection against water EN 1277 Ring Stiffness

Ring Stiffness Impact resistance (EN744)

Impact resistance (EN744) Ring Stiffness EN ISO 13968

Ring Stiffness EN ISO 13968 Application Standard (EN 13476-3)

Application Standard (EN 13476-3)

- PROPERTIES

- CHARACTERISTICS

- PACKAGING

- DOWNLOADS

- PROJECTS

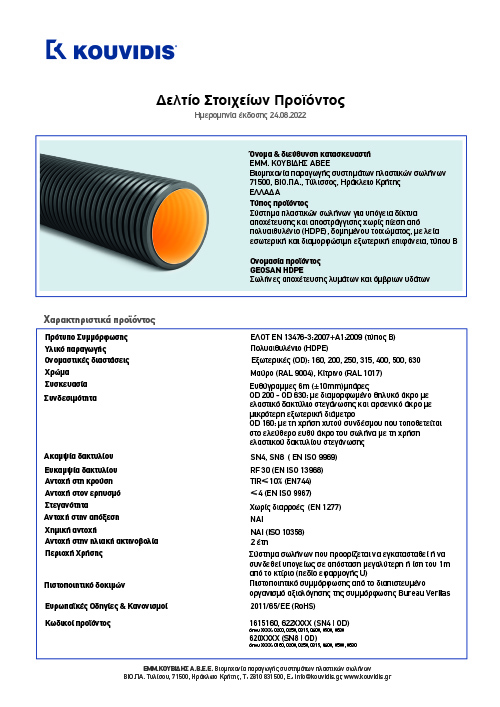

| Properties | |

| European Standard | ΕΝ 13476-3:2007+Α1:2009 |

| Type | Type Β |

| Raw material | Halogen free, heavy metals free (RoHS) and specially stabilized thermoplastic HDPE |

| Ring Stiffness (EN ISO 9969) | SN4 | SN8 |

| Ring Flexibility (EN ISO 13968) | RF30 |

| Impact resistance (EN744) | TIR≤10% |

| Creep Ratio (EN ISO 9967) | ≤4 at 2 years extrapolation |

| Water Tightness (EN 1277) | No leakage |

| Abrasion resistant | Yes |

| Ageing resistance | 2 years |

| Chemical resistance (ISO 10358) | Yes |

| Application area | Pipes and fittings which are to be used buried in the ground outside a building structure only (at least 1m from the structure). |

| Nominal diameters (mm) | Outside (OD): 160, 200, 250, 315, 400, 500, 630 |

| Packaging | 6m bars (±10mm) |

| Connection technology | OD 200 – OD 630: An integrated molded socket with a pre-installed elastomeric sealing ring at the end of the pipe is connected with the other, of a smaller outer diameter, molded end. OD 160: available with an assembled separated molded coupler and an elastomeric sealing ring. |

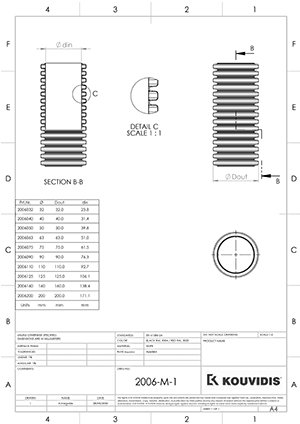

| Part number (SN4) | Part number (SN8) |  |

|

|

|

|

| 1615160 | 1605160 | 160 | 137 | 6.00 | 210 | 2520 |

| 6220200 | 6200200 | 200 | 178 | 6.02 | 120.4 | 1806 |

| 6220250 | 6200250 | 250 | 223 | 6.00 | 72 | 960 |

| 6220315 | 6200315 | 315 | 278 | 5.98 | 71.76 | 574.08 |

| 6220400 | 6200400 | 400 | 347 | 5.94 | 53.46 | 427.68 |

| 6220500 | 6200500 | 500 | 438 | 5.93 | 23.72 | 237.20 |

| 6220630 | 6200630 | 630 | 542 | 5.90 | 29.50 | 188.80 |