Research, Development & Innovation

Our mission

KOUVIDIS is moving along precisely this track. We have consciously chosen the path of growth, research and continuous evolvement. We take care of our customers' needs and we are continuously working so that we are always one step ahead of them. We aim to offer innovative solutions that will protect the installer’s work and will also upgrade a modern building.

We are investing in our people ideas, listening carefully to our customers, choosing the best partners, consulting our country’s university institutions, implementing the relevant legislation, emphasizing on safety and testing our products in independent international recognized certification bodies.

Our 24 patent degrees protected by national or European patent office demonstrate our passion for continuous development of new value-added products that meet the modern challenges.

Innovation is our distinctive advantage

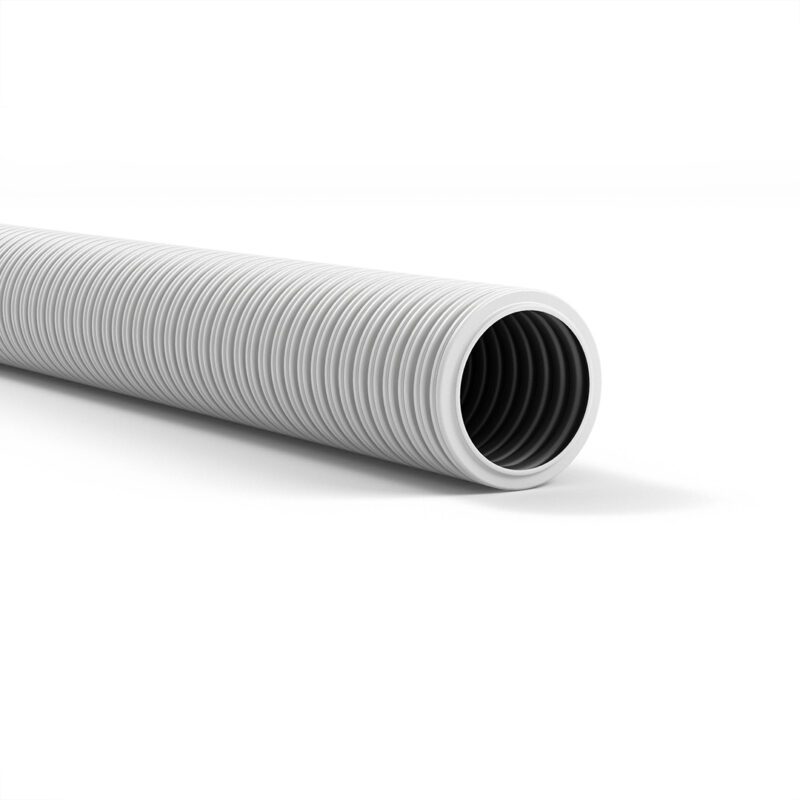

- ANTISCRATCH TECHNOLOGY

- ANTI–ELECTROMAGNETIC TECHNOLOGY

- ANTIMICROBIAL TECHNOLOGY

- COLOR MARKING

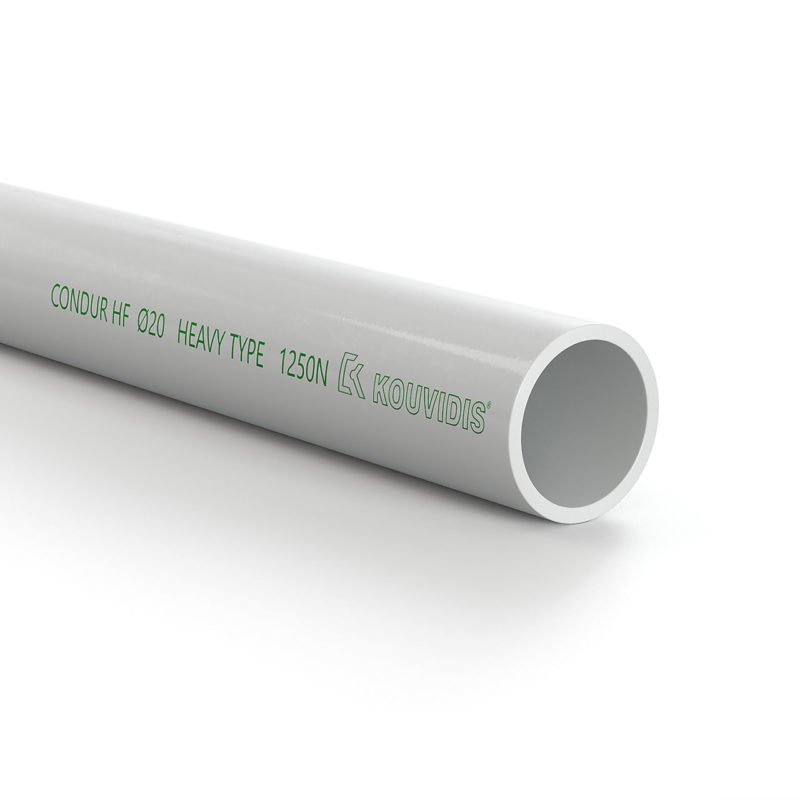

- HALOGEN FREE PRODUCTS

- ANTI–RODENT PROTECTION

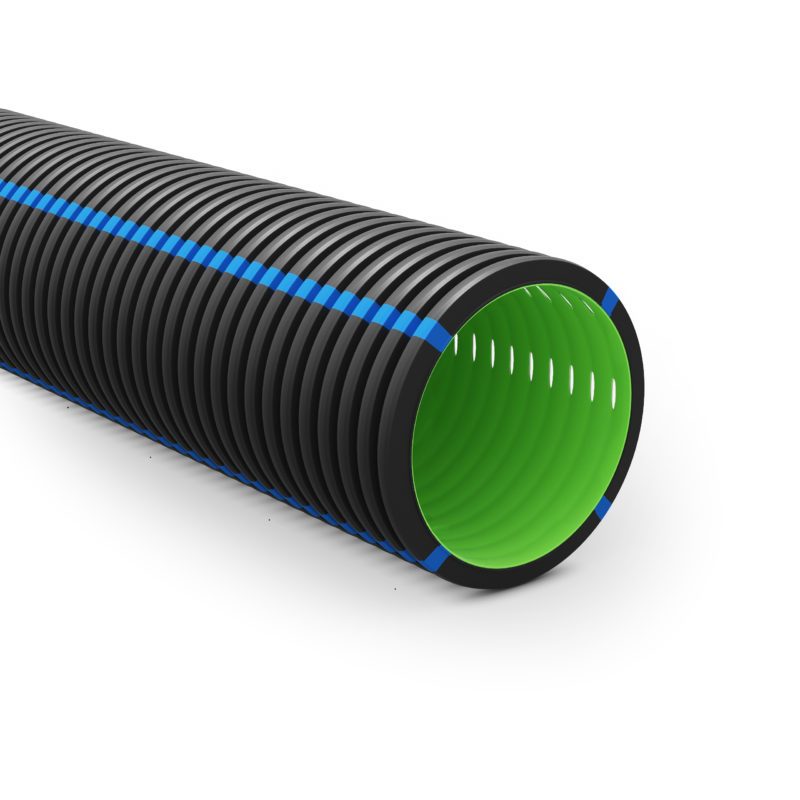

- DOUBLE WALL TECHNOLOGY (DW - HIGH SPEED)

- ANTISTATIC TECHNOLOGY

Cable routing at the inner layer of the conduits can sometimes wear the surface either from the cables or the cable guide that is used to pull the cables within the conduit. To circumvent this phenomenon, KOUVIDIS developed and applied a technology against scratching which minimizes wear at the inner layer of the conduits. This makes the electrical installation safer reassuring that the conduits’ mechanical strength remains untouched, whilst the low friction coefficient is essentially strengthened.

The new generation of 3layer conduits SUPERSOL® PLUS – SUPERFLEX® PLUS and MEDISOL® PLUS – MEDIFLEX® PLUS incorporate an innovative technology which absorbs a part of the electromagnetic radiation emitted by the cables running within the conduit.

KOUVIDIS is the first Greek company to enter the field of production of plastic conduits using anti–electromagnetic technology.

We offer tailor-made solutions depending on application fields demands

Antimicrobial protection reduces the risk of multiplication of the microbes found into the building materials, when is incorporated on their surface, and can be beneficial in keeping the numbers of microbes relatively low in between episodes of cleaning, providing better hygiene conditions.

KOUVIDIS has designed plastic conduit systems with antimicrobial technology exclusively to cover sensitive areas where hygiene is top priority.

The antimicrobial technology incorporated in KOUVIDIS conduit systems can ensure a reduction of up to 99% of the most dangerous pathogenic microbes (MRSA, E-coli) within 24 hours.

Innovation is a part of KOUVIDIS culture since its founder developed the first plastic pipes in 1979 with extra ordinary features that exceeded the steel pipes of that era.

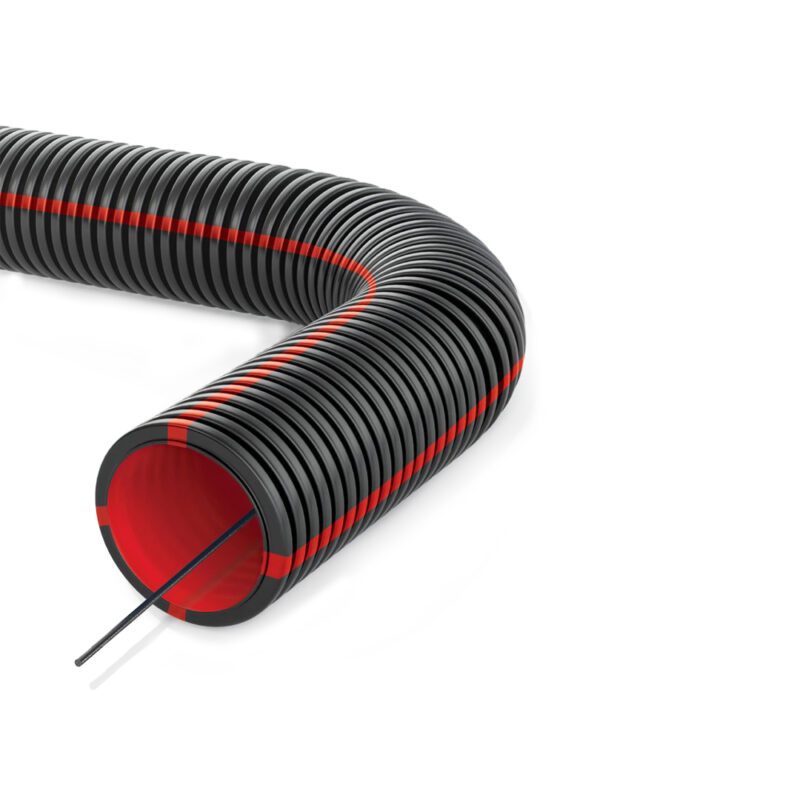

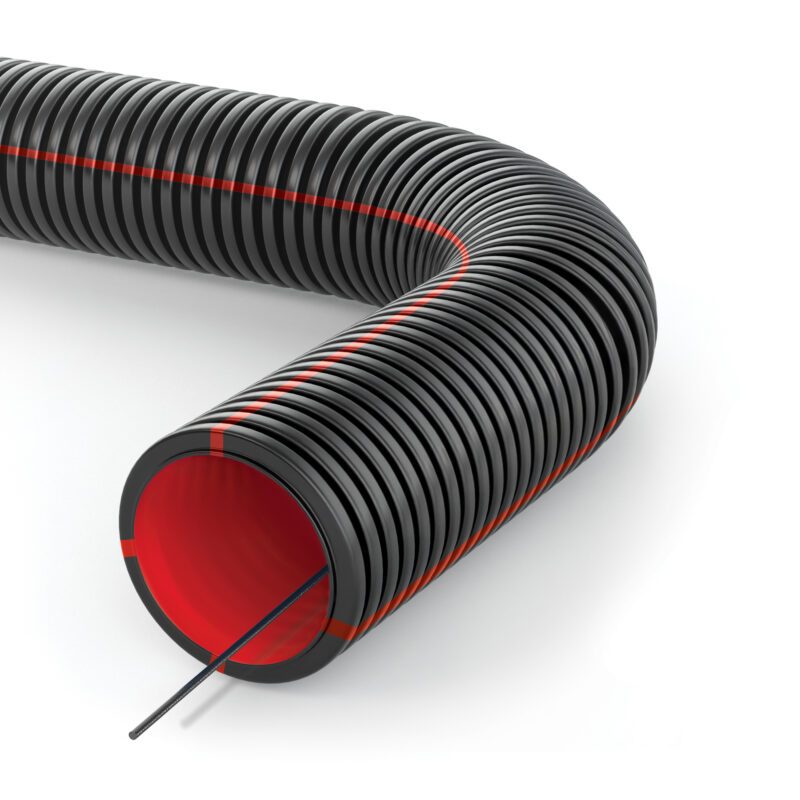

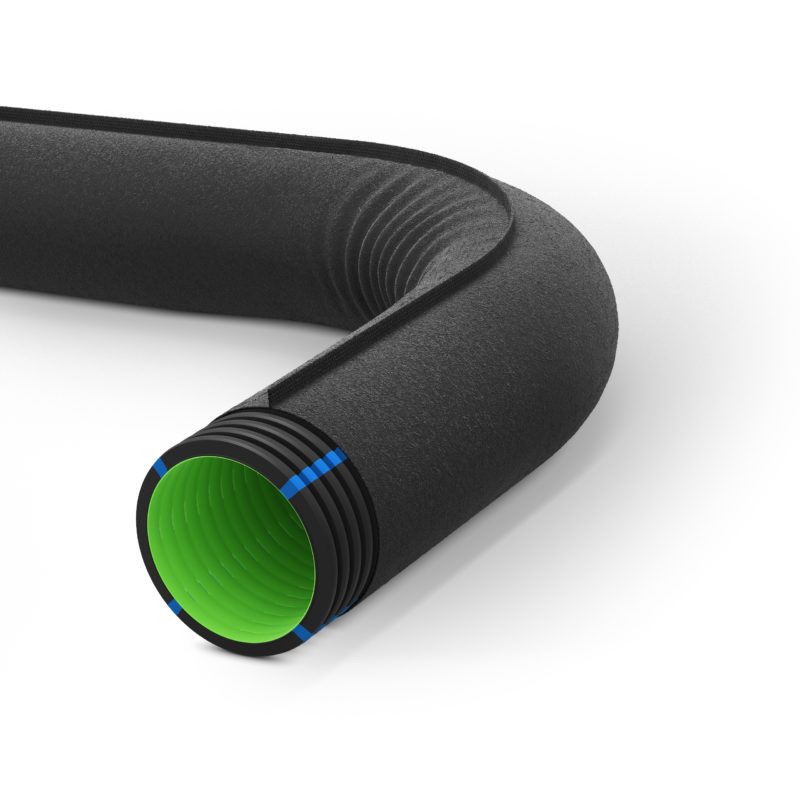

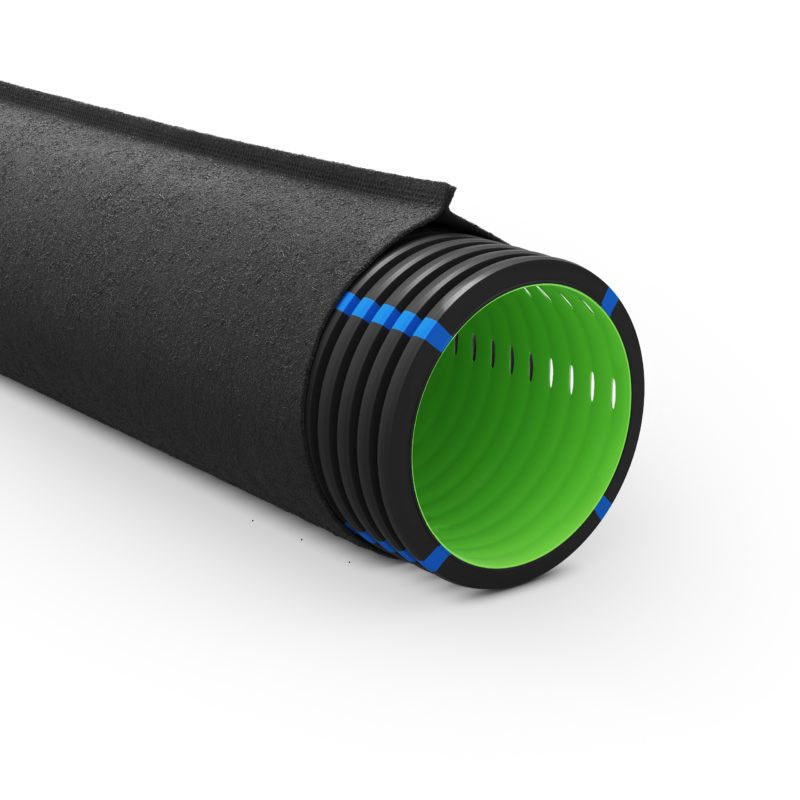

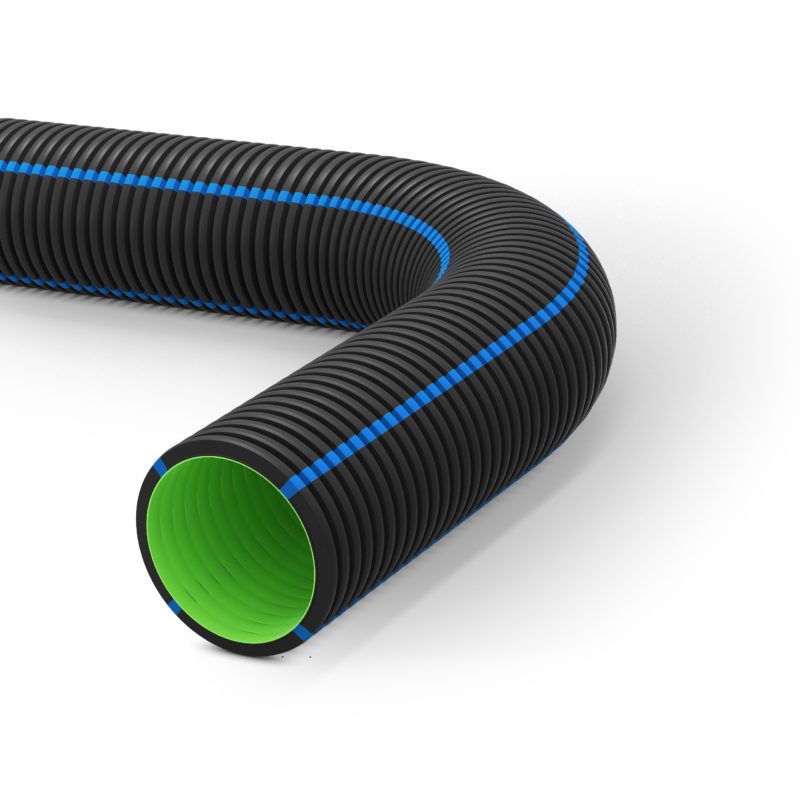

The management and protection of power energy and telecommunication networks, the protection of the personnel performing technical installation or maintenance tasks and the facilitation of engineer’s work providing a better and safer way of networking, led KOUVIDIS to design and invest in the development of plastic pipes with three different walls.

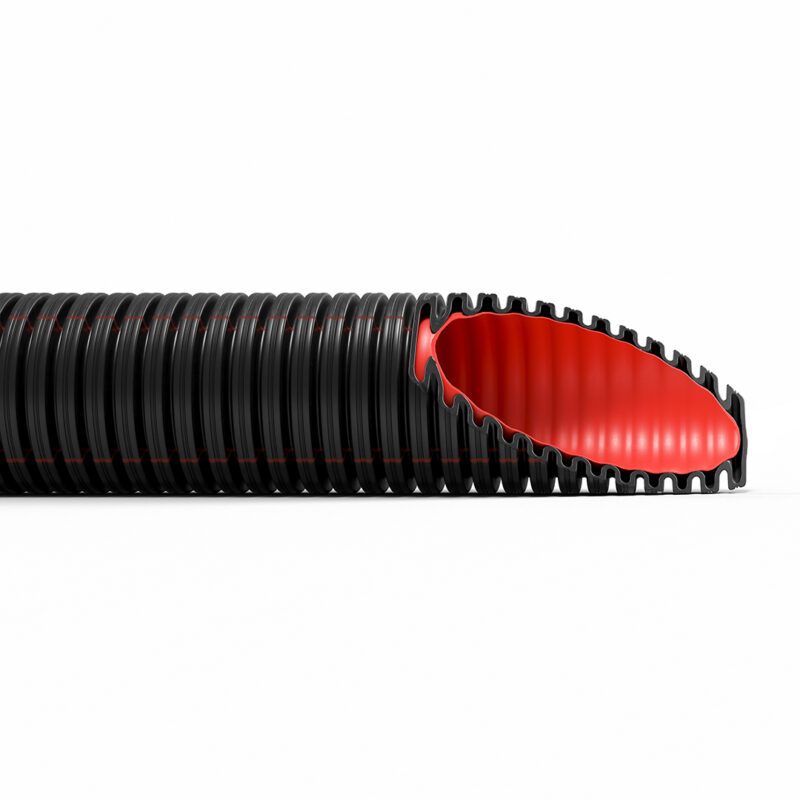

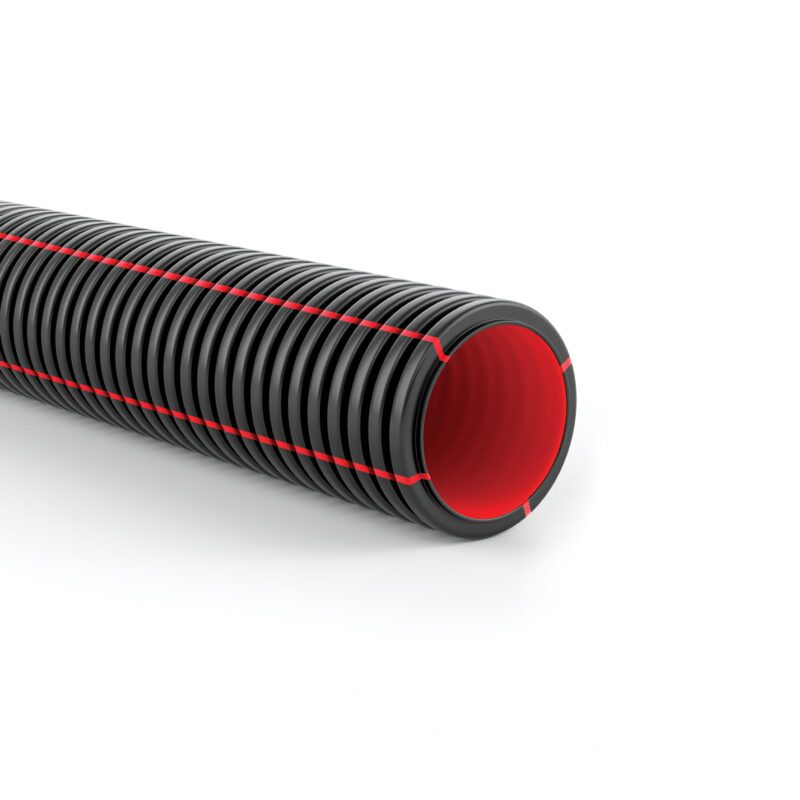

Color marking was presented for the first time in 2017 with the 2nd generation conduits GEONFLEX® N750 and GEOSUB® N450, magnetizing immediately the interest of the installers and upgraded the way of cable protection and management in buried underground networks.

The color identification of the new double structured wall conduits for buried underground networks follows the rules set by the Standard NF P 98-332 which specifies the pipeline coloring according to the application field and the minimum distances buried pipes should have between each other.

To distinguish cables that are routed inside the conduits, a third outer layer is added, which consists of four (4) longitudinal lines, of indelible color.

Red color warns of the existence of power cables, while the green color signals cables with weak currents, such as telecommunications. Blue lines indicate the presence of water, such as in drainage installations.

KOUVIDIS embraced the color identification from buried underground networks and applied the equivalent marking to plastic conduits that are produced for above ground electrical installations. These are the innovative conduit systems DUROSOL® PLUS – DUROFLEX® PLUS and SUPERSOL® PLUS – SUPERFLEX® PLUS. Accordingly, the color marking was adopted to the drainage pipes GEODRAIN® PLUS and GEODRAIN®.

We do not rest, we are continuously working to improve all our products production process

Fire is amongst the most unpredictable threats and possibly one of the major sources of insecurity for communities, especially when occurring indoors, where chances for evacuation are limited.

KOUVIDIS halogen free and low smoke conduit systems have been designed in such a way in order to develop an additional protection in a burning building while they ensure high impact resistance in extreme low temperature conditions.

Even in the more organized spaces, the inspection on the suitability of construction materials should be of paramount importance.

Demanding customers just make us better

The sense of smell of rodents is much more developed than in human. Research has shed light on the fact that the plasticizers and the aromatic odors of polymers, the bright colors and the texture of polymer products are all responsible for rodents being attracted to plastic goods.

A damage in an electrical installation that consists of mainly plastic parts (pipes, junction boxes, cables, etc.), due to a rodent attack, can cause a potential damage to the network and thus an unpredictable cost to repair it. In some cases a potential damage can cause even a fire. KOUVIDIS has developed a series of plastic piping systems with anti-rodent protection in order to maximize safety in electrical installations from potential animal attacks.

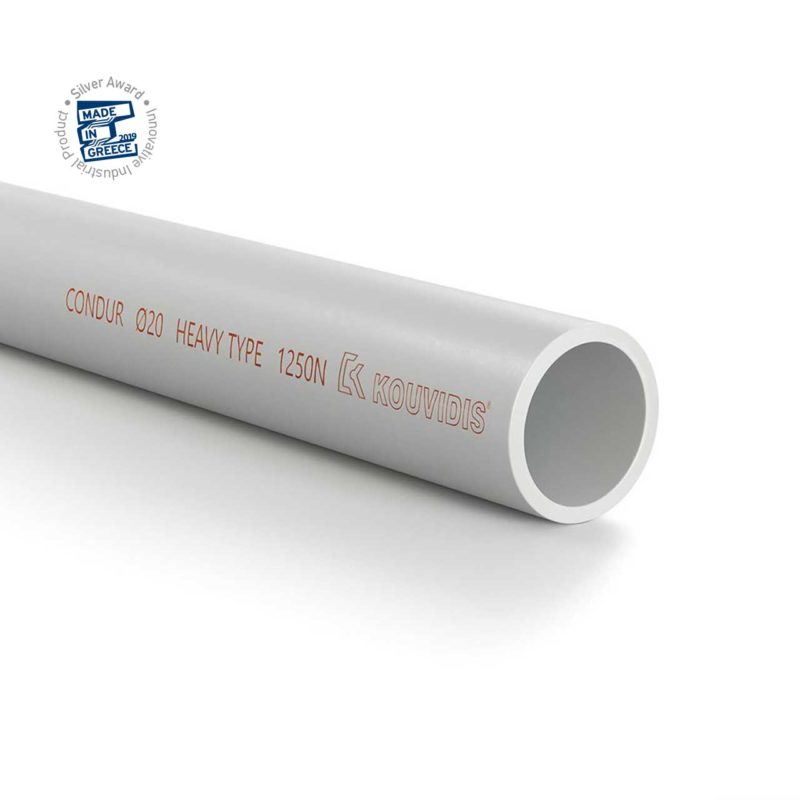

The new generation of 3layer conduits DUROFLEX® PLUS change the way we used to know concealed installations in concrete making electrician’s task even easier while ensuring 100% reliability of his work.

Applying its manufacturing know-how on structured wall conduits in smaller diameters of Ø20, Ø25, Ø32 KOUVIDIS becomes the first company in Europe daring such an investment.

DUROFLEX® PLUS is a Pan- European Innovation that was awarded by the Greek Marketing Academy with the “Innovative Industrial Product” Gold Award in 2019.

Demanding applications are always a challenge for us

Static electricity on surfaces may be noted in cases of friction between the surfaces of cables and the electrical conduit, either during cable installation or as a result of the duct rubbing against its protective membrane packaging.

The presence of static electricity may cause an electrostatic discharge, which, in extreme cases, may even lead to the ignition or explosion of flammable air mixtures (e.g. in industrial bakeries, sugar processing plants, paint factories, chemical processing plants, etc.).

Moreover, the presence of static electricity may damage any electronic and electrical apparatuses that form part of the same electrical installation, alter the readings of measuring instruments, or even cause an electrical injury to people, which may, in turn, lead to accidents.

In order to ensure maximum safety for both the installer and the electrical installation, KOUVIDIS has developed a special additive with multiple active substances, to protect against static electricity, offering an additional safety shield against this phenomenon.